Troubleshooting procedure for CCA melting

If CCA melted,

Check for any smoke or smell in

a) All EMC coils

b) All VEUL’s

c) VEAD

If any abnormality, isolate the same and renew CCA and work further accordingly. If any smoke in VEUL or VEAD remove coil connections. If no abnormality, remove CCLSA, CCAD and place HAD in 0, wedge Q119 in de-energized condition and renew CCA and switch ON BLCPD instead of BLCP. If all EM are not closing, once again check CCA.

If CCA melts again place HOBA in OFF and try.

If CCA melts even HOBA in OFF wedge 2 CP contactors (in Arno locos only) and clear section with 500/500 amps within 5 notches or wedge Q118.

After clearing section, stop the train, take safety precautions and remove the wedges.

1) Renew CCA and close DJ, If CCA melts while switching on BLCP, change the HCP position and renew CCA and resume traction.

2) If MCP contactors are closing, switch ON BLVMT

If CCA melts due to C107 coil defect Keep HVRH in 0 Wedge C107 and renew CCA

3) If CCA melts due to C105 coil defect Keep HVMT-1 in 3 Remove 505 wire. Wedge C105 and renew CCA

4) If CCA melts due to C106 coil defect, Keep HVMT-2 in 3 Remove 510 wire Wedge C106 and renew CCA

5) If CCA melts during RB, Do not use RB.

6) In SIV Loco, If CCA melts while switching on BLCP, change the HCP position, renew CCA and resume traction.

7) In SIV Loco, If CCA melts while switching ON BLVMT, renew CCA, and do not switch ON BLVMT, wedge QSVM, C107, C105, and C106 contactors.

Note: Precautions to be followed for wedging EMC.

In SIV Loco, in midsection if CCA melts even HOBA in off, do not wedge MCP contactors. Contact TLC.

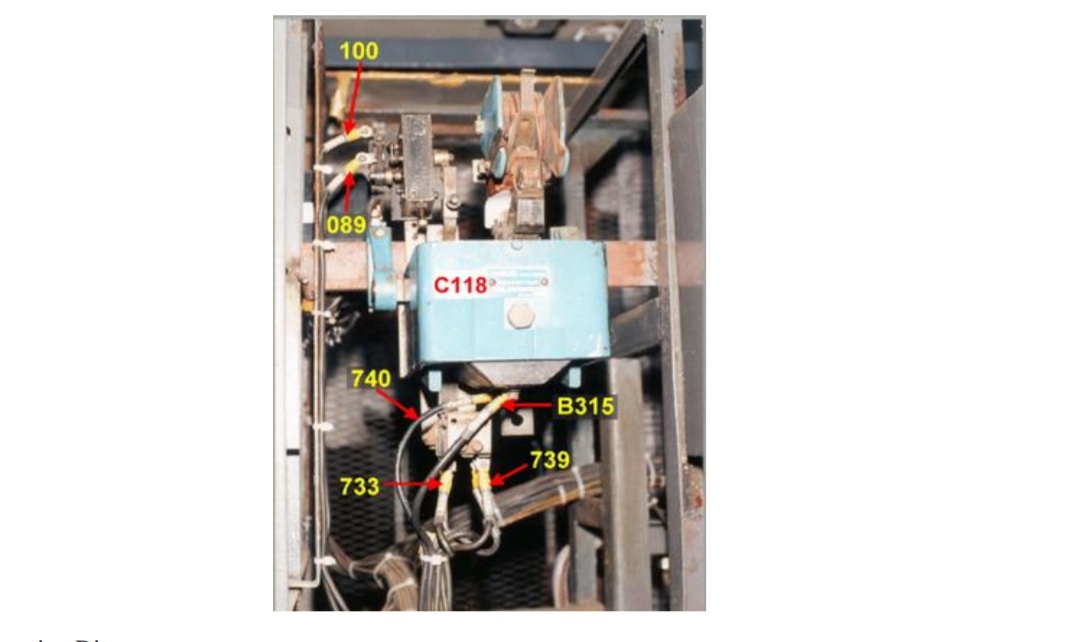

e) In case of WAM4 locos and where Q100 is not available, check the wires 089 & 100 on C118 chronomatic interlock and operate C118 manually after taking safety precautions. If successful, resume traction. In C118 contactor, chronomatic interlock is provided between wire nos.89 & 100 is shown in figure below

C107, C105 & C106 closed but their N/O interlocks are defective.

Place HVMT-1 & HVMT-2 on 3rd position and take 6thnotch. If DJ trips, normalize HVMT 1 and HVMT 2 wedge Q118 in energized condition and resume traction following precautions.

If DJ not tripping on 6th notch, trip DJ, place HVMT-1in 1 and take 6 th notch

If DJ trips change HVMT1 in 3rd position and work up to destination, frequently check the working of MVMT 1. Normalize HVMT 2 If DJ does not trip retain HVMT2 in 3rd position and work up to destination, frequently check the working of MVMT 2.

If CCA melted,

Check for any smoke or smell in

a) All EMC coils

b) All VEUL’s

c) VEAD

If any abnormality, isolate the same and renew CCA and work further accordingly. If any smoke in VEUL or VEAD remove coil connections. If no abnormality, remove CCLSA, CCAD and place HAD in 0, wedge Q119 in de-energized condition and renew CCA and switch ON BLCPD instead of BLCP. If all EM are not closing, once again check CCA.

If CCA melts again place HOBA in OFF and try.

If CCA melts even HOBA in OFF wedge 2 CP contactors (in Arno locos only) and clear section with 500/500 amps within 5 notches or wedge Q118.

After clearing section, stop the train, take safety precautions and remove the wedges.

1) Renew CCA and close DJ, If CCA melts while switching on BLCP, change the HCP position and renew CCA and resume traction.

2) If MCP contactors are closing, switch ON BLVMT

If CCA melts due to C107 coil defect Keep HVRH in 0 Wedge C107 and renew CCA

3) If CCA melts due to C105 coil defect Keep HVMT-1 in 3 Remove 505 wire. Wedge C105 and renew CCA

4) If CCA melts due to C106 coil defect, Keep HVMT-2 in 3 Remove 510 wire Wedge C106 and renew CCA

5) If CCA melts during RB, Do not use RB.

6) In SIV Loco, If CCA melts while switching on BLCP, change the HCP position, renew CCA and resume traction.

7) In SIV Loco, If CCA melts while switching ON BLVMT, renew CCA, and do not switch ON BLVMT, wedge QSVM, C107, C105, and C106 contactors.

Note: Precautions to be followed for wedging EMC.

In SIV Loco, in midsection if CCA melts even HOBA in off, do not wedge MCP contactors. Contact TLC.

e) In case of WAM4 locos and where Q100 is not available, check the wires 089 & 100 on C118 chronomatic interlock and operate C118 manually after taking safety precautions. If successful, resume traction. In C118 contactor, chronomatic interlock is provided between wire nos.89 & 100 is shown in figure below

C107, C105 & C106 closed but their N/O interlocks are defective.

Place HVMT-1 & HVMT-2 on 3rd position and take 6thnotch. If DJ trips, normalize HVMT 1 and HVMT 2 wedge Q118 in energized condition and resume traction following precautions.

If DJ not tripping on 6th notch, trip DJ, place HVMT-1in 1 and take 6 th notch

If DJ trips change HVMT1 in 3rd position and work up to destination, frequently check the working of MVMT 1. Normalize HVMT 2 If DJ does not trip retain HVMT2 in 3rd position and work up to destination, frequently check the working of MVMT 2.