Total Loss of Tractive Effort without GR progression

ABNORMAL SIGN

When MP moved from N to +, LSGR not extinguishing, notch repeater and traction ammeters not deviating and loco not moving.

CAUSES:

1. Q50 not energized (LSB glows)

2. Q51 energized

3. Q52 energized

4. Poor contact of MP conks

5. ZSMS not in proper position

6. ZSMGR not in 6 clock position

7. Less SMGR pressure.

8. GR struck up in 0.

Troubleshooting

1 Q50 not energized when MPJ in F/R (LSB glowing)

Note. In FDCS loco place HOBA in off position and try.

a) Ensure MP on 0, If LSB is glowing, take one notch if progression takes place, ignore LSB and resume traction.

b) If unsuccessful operate MPJ forward/reverse 2 or 3 times. If LSB extinguished, resume traction

c) If LSB not extinguished (Q50 not energized), open DJ, operate BL key 2 or 3 times and close DJ. If LSB extinguishes resume traction.

d) If still Q50 not energized, keep MPJ in required position, trip DJ, switch off HBA take safety precautions e) Place J1, CTF 1, in BA 1 panel, J2,CTF 2 in BA2 panel, CTF 3,C145 in BA3 panel as per MPJ position. For cab-1 leading, manually operate J1, J2 handles and ensure in upward position

For cab-2 leading, manually operate J1, J2 handles and ensure in downward position

f) Ensure all CTF handles should be upward side

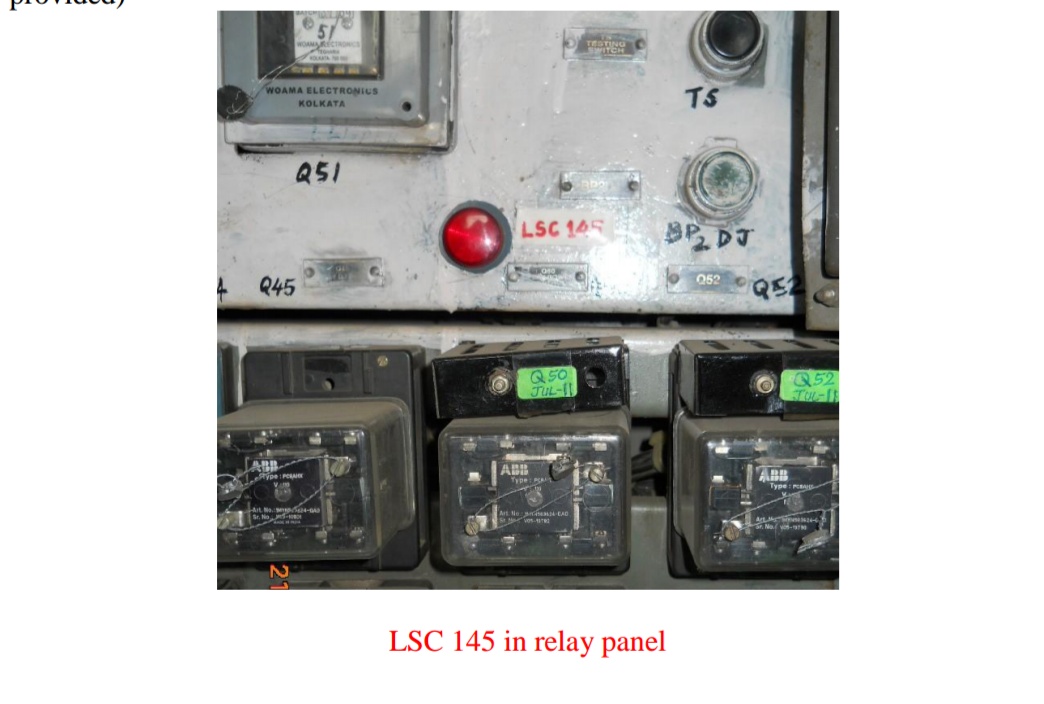

g) C145 open condition (can be ensured by LSC145 in extinguished condition if provided)

h) If LSC145 is glowing, do not wedge Q50 relay.

In WAP4 Locos in addition to the above items check line contactors are fully opened.

i) Close DJ, if Q50 still not energized, wedge Q50 in energized condition and resume traction with precautions.

j) If unsuccessful, clear the block section with manual control of GR with 40 Kmph and contact TLC and act as per his instructions.

NOTE:

In WAG7/WAP (RB) locos, if C145 closed condition/welded condition or heavy leakage in CTF3/C145, close EP3 cut out cock and work without using the RB. (Ensure C145 is open).

Precautions to be followed after wedging Q50

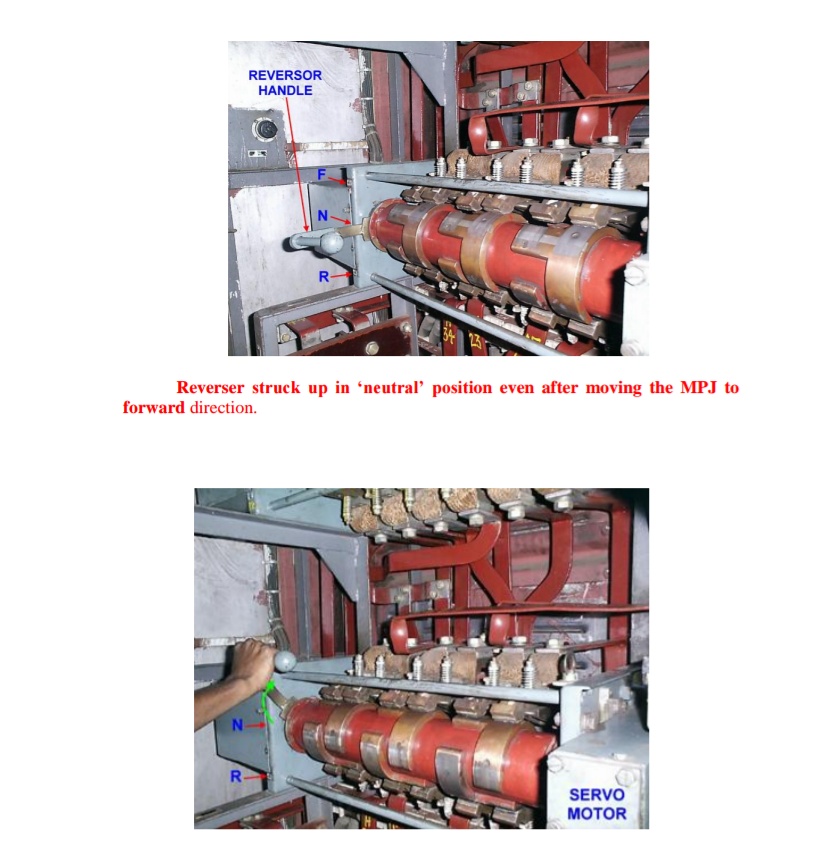

a) Ensure reversers are in required direction if MPJ position is changed.

b) Whenever DJ trips on notches, bring MP to 0 for GR to come to 0 before reclosing DJ.

c) Take few notches and ensue all meters are deviating in both cab

d) Do not use RB.

2 Q51 energized

1) With Auto Flasher Indication (PR 2 energized)

a) Ensure BP pressure AFI readings are normal.

b) If BP pressure dropped troubleshoot for it.

c) If BP pressure is normal, still AFL working, remove CCLSA and work without AFL

d) If unsuccessful, wedge PR1 in energized and work the train.

e) Bring MP to 0 whenever BP pressure drops.

Note: In some locos, if CCLSA is removed VCD cannot be acknowledged through A9,

SA9

2) Without Auto Flasher indication (QRS de-energized)

a) If pilot lamps are not glowing and (BP pressure drops to 0 in CCLS modified loco), renew CCLS and ensure QRS energized. b) If CCLS is intact ensure RGEB cut out cock open

c) Apply A9 to emergency and release and try.

d) If still QRS not energized wedge in energized condition.

e) When QRS is wedged, Bring MP to 0 before applying A9 to emergency

NOTE:

When PR2 and QRS are normal, still Q51energized, get permission from TLC, wedge Q51 in de-energized condition and follow precautions. After wedging Q51, frequently watch Q51 for any overheating Regress the notch a. When TM over voltage buzzer sounds. b. When LSP glows c. When BP pressure drops automatically d. Before applying A9 to emergency bring MP to 0

3. ZSMS not in proper position

Try through MP and EEC in both positions of ZSMS.

4. ZSMGR not in proper position/ less air pressure to SMGR

ABNORMAL SIGN

When MP moved from N to +, LSGR not extinguishing, notch repeater and traction ammeters not deviating and loco not moving.

CAUSES:

1. Q50 not energized (LSB glows)

2. Q51 energized

3. Q52 energized

4. Poor contact of MP conks

5. ZSMS not in proper position

6. ZSMGR not in 6 clock position

7. Less SMGR pressure.

8. GR struck up in 0.

Troubleshooting

1 Q50 not energized when MPJ in F/R (LSB glowing)

Note. In FDCS loco place HOBA in off position and try.

a) Ensure MP on 0, If LSB is glowing, take one notch if progression takes place, ignore LSB and resume traction.

b) If unsuccessful operate MPJ forward/reverse 2 or 3 times. If LSB extinguished, resume traction

c) If LSB not extinguished (Q50 not energized), open DJ, operate BL key 2 or 3 times and close DJ. If LSB extinguishes resume traction.

d) If still Q50 not energized, keep MPJ in required position, trip DJ, switch off HBA take safety precautions e) Place J1, CTF 1, in BA 1 panel, J2,CTF 2 in BA2 panel, CTF 3,C145 in BA3 panel as per MPJ position. For cab-1 leading, manually operate J1, J2 handles and ensure in upward position

For cab-2 leading, manually operate J1, J2 handles and ensure in downward position

f) Ensure all CTF handles should be upward side

g) C145 open condition (can be ensured by LSC145 in extinguished condition if provided)

h) If LSC145 is glowing, do not wedge Q50 relay.

In WAP4 Locos in addition to the above items check line contactors are fully opened.

i) Close DJ, if Q50 still not energized, wedge Q50 in energized condition and resume traction with precautions.

j) If unsuccessful, clear the block section with manual control of GR with 40 Kmph and contact TLC and act as per his instructions.

NOTE:

In WAG7/WAP (RB) locos, if C145 closed condition/welded condition or heavy leakage in CTF3/C145, close EP3 cut out cock and work without using the RB. (Ensure C145 is open).

Precautions to be followed after wedging Q50

a) Ensure reversers are in required direction if MPJ position is changed.

b) Whenever DJ trips on notches, bring MP to 0 for GR to come to 0 before reclosing DJ.

c) Take few notches and ensue all meters are deviating in both cab

d) Do not use RB.

2 Q51 energized

1) With Auto Flasher Indication (PR 2 energized)

a) Ensure BP pressure AFI readings are normal.

b) If BP pressure dropped troubleshoot for it.

c) If BP pressure is normal, still AFL working, remove CCLSA and work without AFL

d) If unsuccessful, wedge PR1 in energized and work the train.

e) Bring MP to 0 whenever BP pressure drops.

Note: In some locos, if CCLSA is removed VCD cannot be acknowledged through A9,

SA9

2) Without Auto Flasher indication (QRS de-energized)

a) If pilot lamps are not glowing and (BP pressure drops to 0 in CCLS modified loco), renew CCLS and ensure QRS energized. b) If CCLS is intact ensure RGEB cut out cock open

c) Apply A9 to emergency and release and try.

d) If still QRS not energized wedge in energized condition.

e) When QRS is wedged, Bring MP to 0 before applying A9 to emergency

NOTE:

When PR2 and QRS are normal, still Q51energized, get permission from TLC, wedge Q51 in de-energized condition and follow precautions. After wedging Q51, frequently watch Q51 for any overheating Regress the notch a. When TM over voltage buzzer sounds. b. When LSP glows c. When BP pressure drops automatically d. Before applying A9 to emergency bring MP to 0

3. ZSMS not in proper position

Try through MP and EEC in both positions of ZSMS.

4. ZSMGR not in proper position/ less air pressure to SMGR

Ensure ZSMGR handle in 6 ‘0’ clock position and operate two or three times and ensure the PACCO switch is in lifted condition. a) Check SMGR pressure and for any air leakage. If SMGR pressure is below 2.5 Kg/cm² or air leaks from SMGR, clear section with manual control of GR and contact TLC. b) Rotate GR 0-5 manually and bring back to 0 and try.

5. Poor contact of MP conks

Check MP conks for proper fittings.

If everything found normal, still GR is not progressing, clear section with manual control of GR.

After clearing section drain out the moisture and try.

If unsuccessful, contact TLC. Note. In FDCS loco place HOBA in off position and try.

NOTE:

1. In some locos, ZSMS position 0 for MP operation and 1 for EEC operation.

2. In modified ZSMS provided locos, ZSMS position 1 for MP operation and 0 for MP&EEC operation.