Impossible to close DJ (ICDJ)

ABNORMAL SIGN:

While trying to re-close DJ, LSDJ remains glowing.

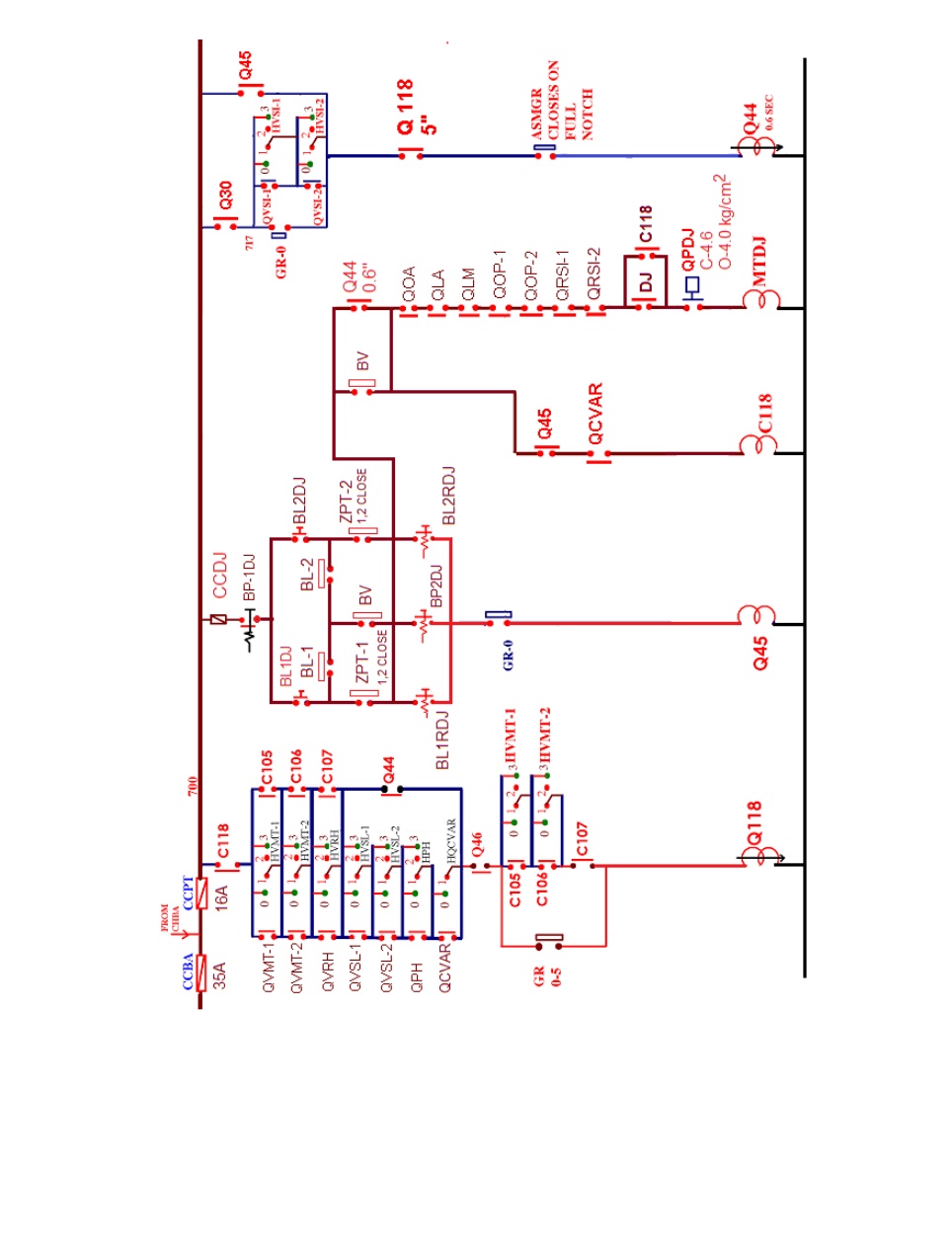

CAUSES:

1. Less battery voltage.

2. Less air pressure.

3. Q118 not energised.

4. Q45 not energised.

5. Q44 not energised.

6. C118 not closed (in ARNO loco)

7. MTDJ coil not energized.

Troubleshooting

Before troubleshooting, ensure the train is stopped at convenient place with A9 and SA9 in applied condition, switch on ZCPA (for a maximum of 10min)

Less battery voltage

If battery voltmeter (UBA) indicates ‘0’ or less than 85 volts, find out the defective battery and isolate the same.

NOTE:

If UBA indicates 0, first change additional CCBA in battery box no.1 and try.

Less air pressure

Ensure PR pressure, if it is less, troubleshoot for PR pressure not building up. Identification of relays in de-energized condition

ABB/BBC/EEC Make: Plunger moves inside when relay is manually pressed.

WOMMA Make: N/O interlocks not closed at coil end.

COMAT Make: Yellow band not visible. (This relay cannot be energized manually and can be wedged in energized condition only)

Q118 not energized

1. Ensure battery voltage is above 85/90 volts.

2. Ensure the pantograph is in raised condition. If it is lowered, troubleshoot for it.

3. Check C118, C105, C106 and C107 are fully opened. If any contactor is welded, rectify the same.

4. Ensure the relays Q44 and Q46 not in energized condition

5. Check GR is on '0' (LSGR is glowing).

6. If everything is normal, manually energise Q118.

Manual energisation of relay Q118 (except for comat make)

1. Close BLDJ and BLVMT, press Q118 manually and press BP2 DJ.

2. Release BP2 DJ after LSDJ, LSCHBA extinguishes and release Q118 after 30 seconds or after all blowers started.

3. If DJ is closed and maintained, resume traction. Every time close DJ as above.

4. If DJ is closed but tripped after releasing Q118, wedge Q118 in energised condition and work with precautions.

Note: Manual Energisation of Q118 is not necessary in SIV locos

Precautions for wedging Q118

a) Before closing DJ ensure all EM contactors are opened.

b) While closing DJ ensure LSCHBA extinguishes, if not, release BLRDJ 4 seconds after extinguishing of LSDJ to protect R118.

c) After closing DJ

1. Ensure C118 is fully opened

2. Check the working of MVMT1 MVMT2 MVRH MVSL1 MVSL2 auxiliary motors.

3. To ensure the working of MPH check TFR oil level & colour change or for any abnormal rise.

4. Avoid quick regression of GR.

NOTE:

Method of wedging for different make of relays is mentioned in the general Instructions chapter.

Q45 not energized

Ensure BLDJ is closed, ZPT is in 1 position, glowing of LSGR, and SMGR drum is in 0.

1. Press and release BP1DJ gently, and then press BP2DJ/Additional BLRDJ instead of BLRDJ and try. If unsuccessful

2. Check CCDJ. If it is melted, renew the fuse.

3. Press BP2DJ and if Q45 still not energizing, once again check CCDJ, if melted second time,

4. Keep HOBA in off, renew CCDJ and energize Q45 manually

5. If once again the fuse is melted, renew the fuse and try from rear cab. If unsuccessful, contact TLC.

6. Change ZPT to other position and try.

7. Rotate GR manually from 0 to 5 notches and back to 0 and try.

8. If unsuccessful, energize Q45 manually.

Manual Energisation of Q45

a) Ensure ZPT in 1 position, BLDJ on, GR in 0 and press Q45 and release it after 4 seconds after extinguishing of LSDJ.

b) If DJ closed, resume traction.

c) Every time close DJ, by manually energizing Q45 duly ensuring GR in 0.

Q44 not energized.

a) Ensure Q118, Q45 are energized, and LSGR is glowing.

b) Operate GR manually 0 to 5 and back to 0 and try to close DJ and resume traction.

c) If unsuccessful, manually energize Q44.

Manual energisation of Q44

a) Ensure BLDJ on, ZPT in 1 and depute ALP to watch RGR.

b) Press BP2DJ (to energize Q45) and press Q44 manually.

c) Release Q44 as soon as DJ is closed and release BP2DJ after extinguishing of LSCHBA.

d) If DJ holds, resume traction. Every time for closing DJ operate Q44 manually.

e) If unsuccessful contact TLC.

NOTE: Q44 should not be wedged.

C118 not closed

a) Switch off HBA and check the C118 wire connections (wire Nos. 740 & B315). If they are disconnected, try to connect them.

b) If wire connections are normal, check the flexibility of the contactor. If it is not moving freely, try to rectify it. If failed, contact TLC.

c) Clean the interlocks of QCVAR and try.

d) If DJ does not close, try from rear cab and clear section.

e) Ensure PR pressure if S118 is provided.(if any cut out cock is provided, ensure it is in open condition)

f) If unsuccessful, contact TLC for further instructions.

NOTE: C118 should not be operated manually for closing DJ.

MTDJ coil not energized

a) Check QLM for locked indication and tap QOP1, QOP2 and QOA if trips troubleshoot for it.

b) In SIV locos check LSSIT/INTERNAL/EXTERNAL fault lamp is glowing. If glows troubleshoot for it. c) Ensure MR/PR pressure is above 6.5 Kg/cm², switch on ZCPA till SS1 blows.

d) Ensure R1and RAL cut out cock open, if closed, open it and try.

e) Check C118 interlock wire connections (739 & 733) are intact. f) If DJ does not close, gently tap VCB cover and QPDJ and try to close DJ.

g) If DJ does not close, place HQOA- 0, HQOP1 and HQOP2- OFF HOBA also in OFF position and try.

h) If DJ is closed, after clearing the block section, open DJ, first normalize HOBA and then, HQOA, HQOP1 & HQOP2 one by one and retain the defective one isolated and follow its precautions.

i) If DJ not closed, drain out moisture and try, still DJ is not closing, contact TLC

Note. In FDCS loco place HOBA in off position and try.

ABNORMAL SIGN:

While trying to re-close DJ, LSDJ remains glowing.

CAUSES:

1. Less battery voltage.

2. Less air pressure.

3. Q118 not energised.

4. Q45 not energised.

5. Q44 not energised.

6. C118 not closed (in ARNO loco)

7. MTDJ coil not energized.

Troubleshooting

Before troubleshooting, ensure the train is stopped at convenient place with A9 and SA9 in applied condition, switch on ZCPA (for a maximum of 10min)

Less battery voltage

If battery voltmeter (UBA) indicates ‘0’ or less than 85 volts, find out the defective battery and isolate the same.

NOTE:

If UBA indicates 0, first change additional CCBA in battery box no.1 and try.

Less air pressure

Ensure PR pressure, if it is less, troubleshoot for PR pressure not building up. Identification of relays in de-energized condition

ABB/BBC/EEC Make: Plunger moves inside when relay is manually pressed.

WOMMA Make: N/O interlocks not closed at coil end.

COMAT Make: Yellow band not visible. (This relay cannot be energized manually and can be wedged in energized condition only)

Q118 not energized

1. Ensure battery voltage is above 85/90 volts.

2. Ensure the pantograph is in raised condition. If it is lowered, troubleshoot for it.

3. Check C118, C105, C106 and C107 are fully opened. If any contactor is welded, rectify the same.

4. Ensure the relays Q44 and Q46 not in energized condition

5. Check GR is on '0' (LSGR is glowing).

6. If everything is normal, manually energise Q118.

Manual energisation of relay Q118 (except for comat make)

1. Close BLDJ and BLVMT, press Q118 manually and press BP2 DJ.

2. Release BP2 DJ after LSDJ, LSCHBA extinguishes and release Q118 after 30 seconds or after all blowers started.

3. If DJ is closed and maintained, resume traction. Every time close DJ as above.

4. If DJ is closed but tripped after releasing Q118, wedge Q118 in energised condition and work with precautions.

Note: Manual Energisation of Q118 is not necessary in SIV locos

Precautions for wedging Q118

a) Before closing DJ ensure all EM contactors are opened.

b) While closing DJ ensure LSCHBA extinguishes, if not, release BLRDJ 4 seconds after extinguishing of LSDJ to protect R118.

c) After closing DJ

1. Ensure C118 is fully opened

2. Check the working of MVMT1 MVMT2 MVRH MVSL1 MVSL2 auxiliary motors.

3. To ensure the working of MPH check TFR oil level & colour change or for any abnormal rise.

4. Avoid quick regression of GR.

NOTE:

Method of wedging for different make of relays is mentioned in the general Instructions chapter.

Q45 not energized

Ensure BLDJ is closed, ZPT is in 1 position, glowing of LSGR, and SMGR drum is in 0.

1. Press and release BP1DJ gently, and then press BP2DJ/Additional BLRDJ instead of BLRDJ and try. If unsuccessful

2. Check CCDJ. If it is melted, renew the fuse.

3. Press BP2DJ and if Q45 still not energizing, once again check CCDJ, if melted second time,

4. Keep HOBA in off, renew CCDJ and energize Q45 manually

5. If once again the fuse is melted, renew the fuse and try from rear cab. If unsuccessful, contact TLC.

6. Change ZPT to other position and try.

7. Rotate GR manually from 0 to 5 notches and back to 0 and try.

8. If unsuccessful, energize Q45 manually.

Manual Energisation of Q45

a) Ensure ZPT in 1 position, BLDJ on, GR in 0 and press Q45 and release it after 4 seconds after extinguishing of LSDJ.

b) If DJ closed, resume traction.

c) Every time close DJ, by manually energizing Q45 duly ensuring GR in 0.

Q44 not energized.

a) Ensure Q118, Q45 are energized, and LSGR is glowing.

b) Operate GR manually 0 to 5 and back to 0 and try to close DJ and resume traction.

c) If unsuccessful, manually energize Q44.

Manual energisation of Q44

a) Ensure BLDJ on, ZPT in 1 and depute ALP to watch RGR.

b) Press BP2DJ (to energize Q45) and press Q44 manually.

c) Release Q44 as soon as DJ is closed and release BP2DJ after extinguishing of LSCHBA.

d) If DJ holds, resume traction. Every time for closing DJ operate Q44 manually.

e) If unsuccessful contact TLC.

NOTE: Q44 should not be wedged.

C118 not closed

a) Switch off HBA and check the C118 wire connections (wire Nos. 740 & B315). If they are disconnected, try to connect them.

b) If wire connections are normal, check the flexibility of the contactor. If it is not moving freely, try to rectify it. If failed, contact TLC.

c) Clean the interlocks of QCVAR and try.

d) If DJ does not close, try from rear cab and clear section.

e) Ensure PR pressure if S118 is provided.(if any cut out cock is provided, ensure it is in open condition)

f) If unsuccessful, contact TLC for further instructions.

NOTE: C118 should not be operated manually for closing DJ.

MTDJ coil not energized

a) Check QLM for locked indication and tap QOP1, QOP2 and QOA if trips troubleshoot for it.

b) In SIV locos check LSSIT/INTERNAL/EXTERNAL fault lamp is glowing. If glows troubleshoot for it. c) Ensure MR/PR pressure is above 6.5 Kg/cm², switch on ZCPA till SS1 blows.

d) Ensure R1and RAL cut out cock open, if closed, open it and try.

e) Check C118 interlock wire connections (739 & 733) are intact. f) If DJ does not close, gently tap VCB cover and QPDJ and try to close DJ.

g) If DJ does not close, place HQOA- 0, HQOP1 and HQOP2- OFF HOBA also in OFF position and try.

h) If DJ is closed, after clearing the block section, open DJ, first normalize HOBA and then, HQOA, HQOP1 & HQOP2 one by one and retain the defective one isolated and follow its precautions.

i) If DJ not closed, drain out moisture and try, still DJ is not closing, contact TLC

Note. In FDCS loco place HOBA in off position and try.